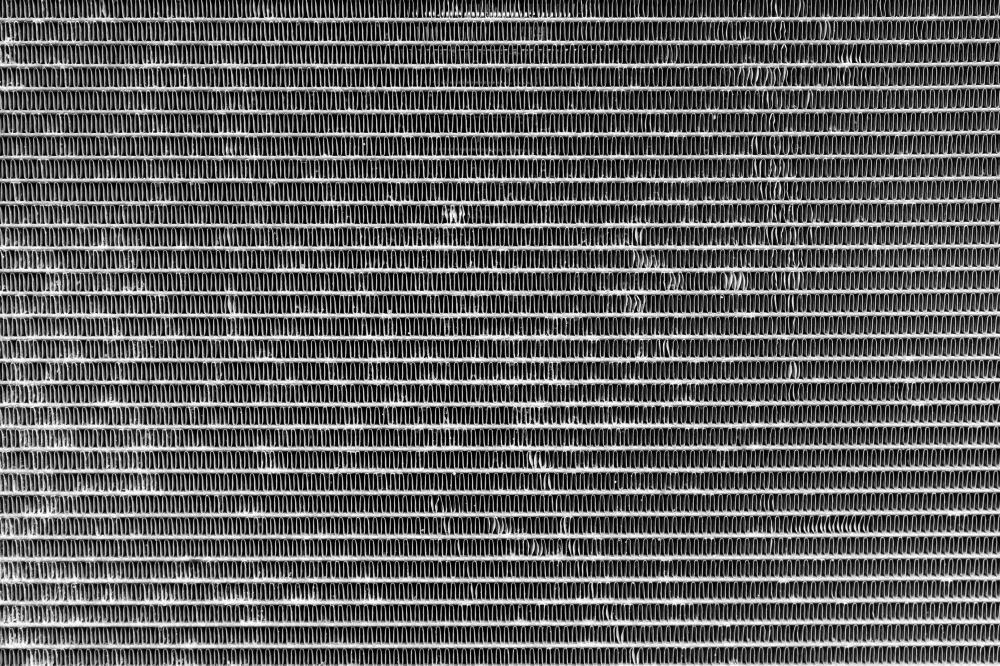

Understanding Condenser Coils

At American Coil, Inc., we specialize in the design and manufacture of high-quality condenser coils, among other HVAC solutions. A condenser coil is an essential component in your HVAC system, playing a pivotal role in the heat transfer process. It's where the refrigerant gas releases the heat absorbed from your indoor space and condenses back into a liquid. This fundamental process is at the heart of cooling systems, refrigerators, and air conditioning units, ensuring they function efficiently to maintain comfortable indoor temperatures and air quality.

Design and Manufacturing

We take pride in our ability to produce condenser coils tailored to meet the specific needs of our clients. Our coils come in both aluminum and copper fin configurations to cater to varying preferences and requirements. The choice between aluminum and copper often depends on factors such as thermal conductivity, corrosion resistance, and budget considerations.

The tube diameters we offer range from 5/16 inches to 5/8 inches, with wall thicknesses varying to ensure durability and efficiency. This flexibility allows us to customize coils for any application, whether it's for commercial, industrial, or residential use.

AmeriCoat™ Coating System

One innovative solution we've developed at American Coil is our proprietary AmeriCoat™ anti-corrosion coating system. This advanced coating significantly enhances the durability of our coils, effectively reducing maintenance needs and prolonging their service life. The AmeriCoat™ system is tested to withstand over 10,000 hours of salt spray, proving its resilience and effectiveness in protecting coils from harsh environmental conditions.

Less than 1% heat transfer degradation occurs with this coating, ensuring that the efficiency of your HVAC system is not compromised. Our dedication to innovation and quality makes AmeriCoat™ a standout solution for extending the lifespan and maintaining the performance of your HVAC components.

Customization and Flexibility

Understanding that each project has its unique challenges, we offer unparalleled customization for our condenser coils. Our interactive quotation system allows clients to input specific requirements, providing instant estimates that help streamline decision-making processes. This user-friendly tool ensures that our clients can easily specify their needs, from fin thickness to circuiting options, ensuring a perfect fit for their systems.

From the initial design phase to the final delivery, our team works closely with clients to tailor the best HVAC solutions. Our commitment to customization not only meets but often exceeds client expectations, reinforcing our position as a leader in the coil manufacturing industry.

The Importance of Quality

At American Coil, we understand that the quality of condenser coils directly impacts the efficiency and longevity of HVAC systems. That's why we do not compromise on the materials and processes used in manufacturing our products. Our rigorous testing and quality control measures ensure that each coil we produce meets the highest standards of performance and reliability.

Our low warranty rates and the positive feedback from our clients testify to our dedication to quality. Whether you're an OEM manufacturer or managing commercial properties, partnering with us means investing in solutions that deliver outstanding performance, durability, and value.

Environmental Considerations

As part of our commitment to sustainability and environmental stewardship, we continuously explore ways to minimize our ecological footprint. The AmeriCoat™ coating system is just one example of our efforts to produce environmentally friendly products. By prolonging the life of HVAC components, we help reduce waste and encourage more sustainable practices within the industry.

Additionally, our efficient manufacturing processes aim to lower energy consumption and decrease emissions, aligning with global initiatives to combat climate change. Choosing American Coil means partnering with a company that cares about the planet and is actively working towards a more sustainable future.

Client-Focused Service

Our reputation as a trusted manufacturer is not just built on the quality of our products, but also on the exceptional service we provide. With an average production lead time of just 10 to 12 business days, we ensure that our clients receive their custom HVAC coils promptly. This efficiency helps minimize downtime and keeps projects on schedule.

Our commitment to impeccable service extends beyond timely deliveries. We offer comprehensive support throughout the lifespan of our products, from technical assistance during installation to maintenance tips for optimizing performance. Our team is always ready to provide the expertise and support our clients need to keep their HVAC systems running smoothly.

In conclusion, at American Coil, the emphasis is on quality, customization, and customer satisfaction. We're more than just a coil manufacturer; we're a dedicated partner in providing HVAC solutions that meet the exact needs of our clients. By choosing American Coil, you're investing in reliability, efficiency, and service that surpasses expectations.

How do I know if my condenser coil is bad?

Recognizing a failing condenser coil in your HVAC system is crucial for maintaining its efficiency and longevity. Signs that may indicate a problem include increased energy bills, reduced cooling efficiency, strange noises coming from the unit, and the system cycling on and off more frequently than usual. If you notice your indoor space isn't cooling as effectively, or if there's visible damage or excessive dirt on the coils, it's time to give us a call at American Coil, Inc. Sometimes, it can be as straightforward as a performance issue where your system isn't providing the comfort it used to. Remember, early detection and repair can save you from more significant, costly problems down the line.

How much does it cost to replace a condensing coil?

The cost to replace a condensing coil can vary widely depending on several factors, including the type of system you have, the size of the coil, and whether you choose aluminum or copper fin configurations. Generally, you're looking at a range that could be anywhere from a few hundred dollars to several thousand, including labor and materials. At American Coil, Inc., we understand that cost is a significant concern, which is why we offer competitive pricing without compromising on quality. We also provide a detailed quotation before any work begins, ensuring there are no surprises. Our goal is to provide you with the best possible solution that fits your budget and needs.

What is the difference between an evaporator coil and a condenser coil?

While both are crucial to the HVAC system's functionality, the evaporator and condenser coils have distinct roles. The evaporator coil is located inside the air handling unit and is responsible for absorbing heat from the air inside your space, using refrigerant. On the flip side, the condenser coil, usually located outside, expels that absorbed heat into the outdoor air. Think of the evaporator coil as the 'chiller' and the condenser coil as the 'releaser.' This partnership between absorption and release is what keeps your environment comfortable. At American Coil, Inc., we specialize in both, ensuring your system works seamlessly.

Do you need to clean AC condenser coils?

Absolutely. Regular cleaning of your AC condenser coils is vital for maintaining the efficiency and longevity of your HVAC system. Dirt, debris, and other particulates can accumulate on the coils, hindering their ability to transfer heat effectively. This buildup forces your system to work harder, leading to increased energy usage and higher utility bills. Moreover, neglect can significantly shorten the lifespan of your unit. We recommend a professional cleaning at least once a year, but the frequency might need to increase depending on your environment and system usage. Keeping those coils clean is a simple yet effective way to ensure your system runs efficiently.

Why choose aluminum or copper for condenser coils, and how does it affect performance?

Choosing between aluminum and copper for condenser coils boils down to factors like cost, thermal conductivity, and corrosion resistance. Copper has excellent thermal conductivity and is easier to repair, making it a choice for those prioritizing efficiency and longevity. However, copper is typically more expensive than aluminum, which is lighter and also provides good corrosion resistance and cost-effectiveness. At American Coil, Inc., we offer both options to cater to our clients' diverse needs and budgets. Understanding the specific demands of your system and environment can guide this choice. In essence, both materials have their advantages, and our team can help you weigh these against your requirements to find the best solution for your HVAC system.

Resources

- Environmental Protection Agency (EPA) - The EPA website provides information on environmental regulations and sustainability practices that can help businesses reduce their ecological footprint.

- U.S. Department of Energy - The Department of Energy offers resources on energy efficiency, renewable energy, and sustainability initiatives to promote environmentally friendly practices.

- National Renewable Energy Laboratory (NREL) - NREL conducts research and development on renewable energy technologies, including HVAC systems, to promote energy efficiency and environmental sustainability.

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) - ASHRAE provides technical resources and guidelines for HVAC design, installation, and maintenance to optimize system performance and energy efficiency.

- U.S. Green Building Council (USGBC) - The USGBC offers information on green building practices and LEED certification to promote sustainable building design and operation.